1. Why you need wastewater treatment system?

1. 100% recycling of waste water, reduced public water supply consumption.

2. Our wastewater treatment system can help extend the service life of glass manufacturing machinery, improve performance, reduce maintenance costs.

3. Improve the quality and appearance of tempered glass.

4. Wastewater treatment system help reduce production line downtime, increase production efficiency.

5. Reduce environmental pollution.

2. Two kinds of wastewater treatment system solution for choice

A. Flocculation Precipitation Reaction

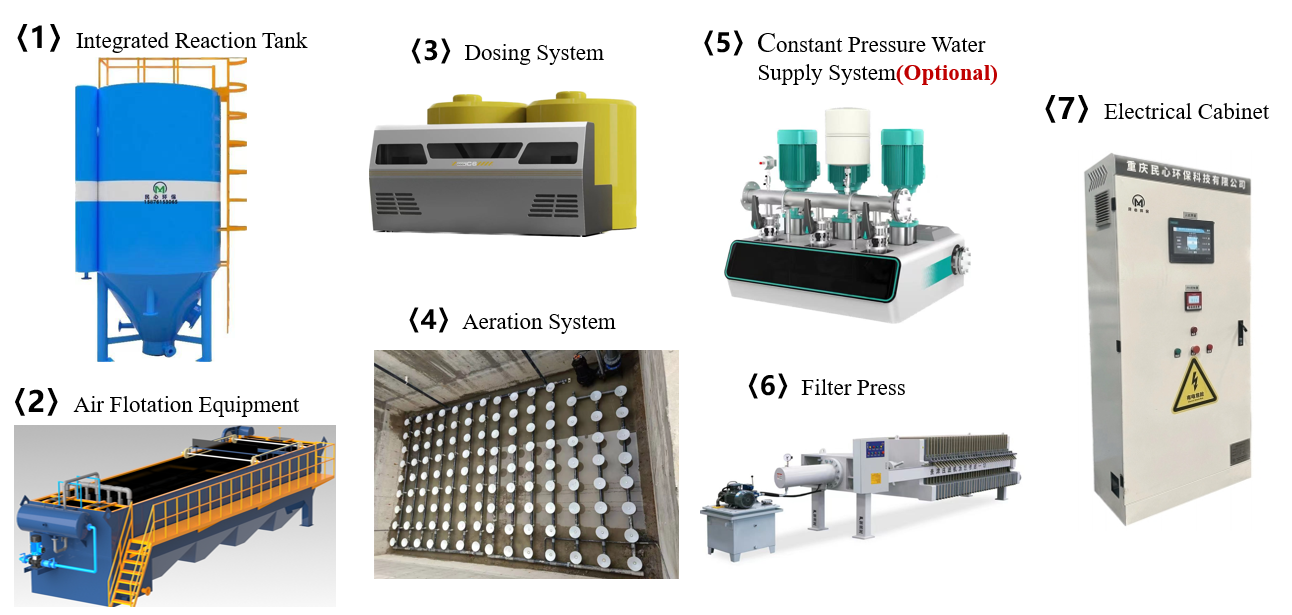

![]() The working process of this wastewater treatment system is to collect wastewater discharged from multiple glass edging machines or beveling machine, drill machine, CNC etc into a wastewater pool, an aeration device is installed at the bottom of the wastewater collection pool, to avoid the glass powder precipitate on the bottom of the pool. Greatly improve the efficiency of cleaning glass powder and reduce cleaning costs. The integrated reaction tank integrates water pumping, dosing, reaction and drain, The treated clean water is flow into the clean water pool and recycling for the glass edging, which can greatly reduce the blockage and damage of the water outlet nozzle of the glass edging machine, prolong the service life of the machine, and improve the grinding efficiency. The glass powder is discharged into the sludge pool, and then pumped to the filter press to press it into solid glass cake, which can be treated directly to avoid environmental pollution.

The working process of this wastewater treatment system is to collect wastewater discharged from multiple glass edging machines or beveling machine, drill machine, CNC etc into a wastewater pool, an aeration device is installed at the bottom of the wastewater collection pool, to avoid the glass powder precipitate on the bottom of the pool. Greatly improve the efficiency of cleaning glass powder and reduce cleaning costs. The integrated reaction tank integrates water pumping, dosing, reaction and drain, The treated clean water is flow into the clean water pool and recycling for the glass edging, which can greatly reduce the blockage and damage of the water outlet nozzle of the glass edging machine, prolong the service life of the machine, and improve the grinding efficiency. The glass powder is discharged into the sludge pool, and then pumped to the filter press to press it into solid glass cake, which can be treated directly to avoid environmental pollution.

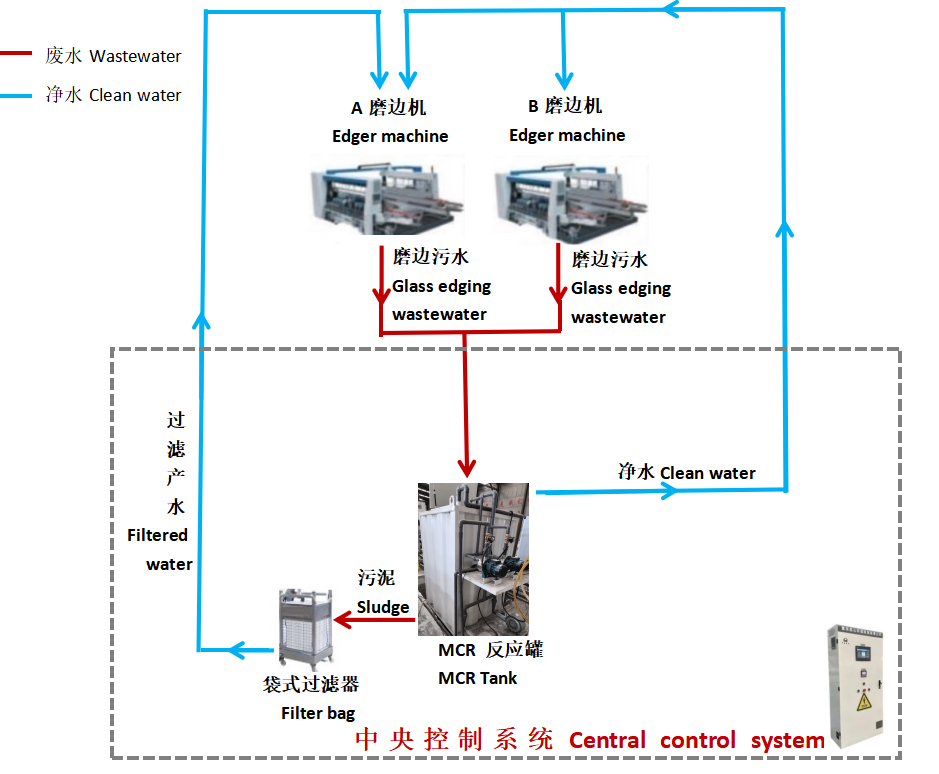

B. Ultrafiltration Membrane Filtration

Ultrafiltration membrane is a polymer semi permeable membrane used in the ultrafiltration process to separate a certain size of polymer colloid or suspended particles from the solution. Driven by pressure, the membrane has a pore size of 1-100nm and belongs to the asymmetric membrane type. The pore density is about 10/cm, and the operating pressure diference is 100-1000kPa. lt is suitable for removing colloidal grade particles and macromolecules, and can separate solutions with a concentration of less than10%. Ultrafiltration uses a new technology of hollow fiber filtration, combined with tertiary pre-treatment filtration to remove impurities from wastewater. Ultrafiltration with micropores smaller than 0.01 micrometers can completely remove harmful substances such as bacteria, rust and colloids from water, while retaining the original trace elements and minerals in the water. The glass powder in wastewater will discharge into the filter bag.

3. Glass industry water treatment equipment configuration

4. Clear water quality after treatment

| No | Water inlet quality | Test item | Clear water quality |

| 1 | Edging wastewater | PH | 7~8.5 |

| 2 | Edging wastewater | SS(mg/L) | <30 |

| 3 | Edging wastewater | COD(mg/L) | <20 |

| 4 | Edging wastewater | Chroma | <30 |

| 5 | Edging wastewater | AMMONIA(mg/L) | <15 |

5. More than 600 installation cases in total