1. Integrated air flotation equipment for glass industry wastewater

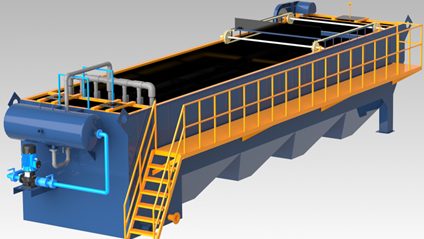

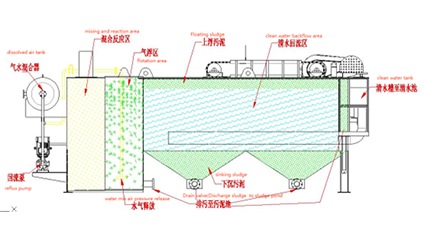

The high-efficiency all-in-one machine for grinding wastewater is a unique equipment developed specifically for the characteristics of glass wastewater. It mainly relies on air flotation technology (micro-nano bubble generation, sub-surface capture, bubble layer interception, etc.) and cocurrent sedimentation principles.

The micro-nano bubble generation device uses clean water or partially treated return water to inhale and mix air through the micro-nano bubble generator to form dissolved air water, which is released under reduced pressure in the equipment pool to form bubbles with a diameter of 0.1~20 μm. The air dissolved in the water is precipitated in the form of micro-nano bubbles, which has a high surface area and adsorption capacity.

It can effectively remove suspended solids in wastewater of different concentrations. After treatment, part of the clean water (reflux ratio 30%) is passed through the circulating working pump. , pressurized into the air-dissolving equipment to mix with air, and the air dissolves into the water. At this time, the air-dissolving efficiency reaches more than 95%. The air dissolved in the water is released from the water to form a microbubble layer with a particle size of micro and nanometers.

The microbubble layer "intercepts" and "filters" the suspended matter in the sewage, greatly increasing the hydraulic load of the equipment. The "intercepted" suspended solids rise to the surface of the water body and form a large amount of scum, which is then removed by a chain-type slag discharger installed on the equipment pool to achieve the treatment effect. The co-current sedimentation technology is mainly used to remove particulate matter with a large specific gravity in the wastewater.

The wastewater after mixing and contacting with micro-bubbles flows downward in an approximate laminar flow state in the separation zone of the device. At this time, the particulate matter with a large specific gravity is controlled by gravity and water flow. Under the dual action, it quickly sinks to the bottom of the pool, and a sludge bucket is set at the bottom of the separation area to achieve the functions of sludge collection and sludge discharge. A backflush device is added to the sludge discharge pipeline. When the sludge hopper has difficulty in sludge discharge, the backflush device is turned on and the sludge at the bottom returns to a smooth sludge discharge state.

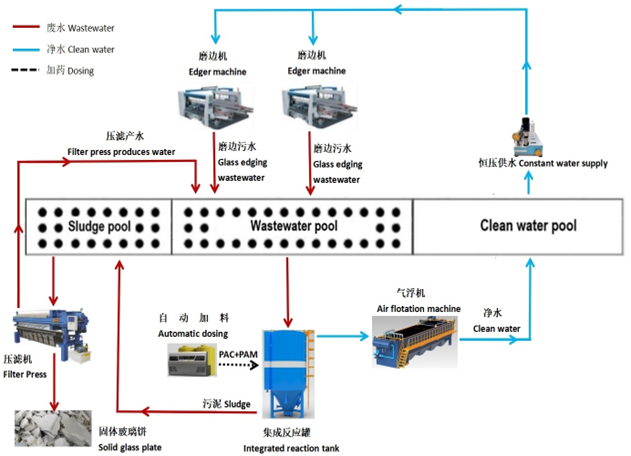

2. Wastewater Solution

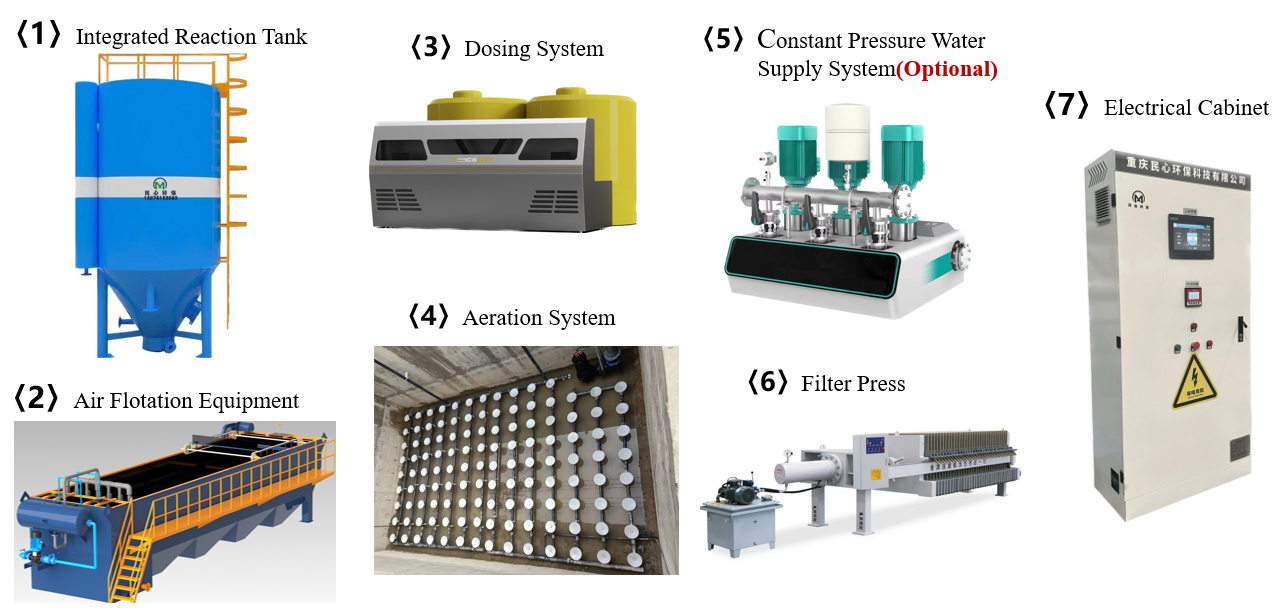

3. Glass industry wastewater treatment Configuration

4.Treatment water quality effect

| No | Item | Water inlet quality | Purified water quality |

| 1 | PH | Edging wastewater | 6~9 |

| 2 | SS(mg/L) | Edging wastewater | <30 |

| 3 | COD(mg/L) | Edging wastewater | <60 |

| 4 | Color | Edging wastewater | <30 |

| 5 | AMMONIA(mg/L) | Edging wastewater | <25 |

5. More than 600 installation cases in total