1. Why choose glass grinding water treatment solution ?

>. Untreated edging wastewater causes the edge grinding cleaning machine to be unclean, resulting in a decrease in light transmittance after tempering the glass, an increase in tempering pits, and a reduction in the service life of the ceramic roller;

>. Untreated edging wastewater will cause frequent blockage of the water inlet pipe of the edging machine, causing trouble to shut down the machine for cleaning, burning the glass edge, and reducing the life of the grinding wheel by 31.8%;

>. The high concentration of glass powder in untreated edging wastewater will cause fine scratches on the surface of coated glass and large plate glass during the edge grinding and cleaning process;

>. Untreated edging wastewater will increase the frequency of water changes in the cleaning machine, resulting in waste of costs;

>. The edging circulation pool needs to be cleaned every six months, which results in high costs, difficulty in handling water treatment, and downtime that affects production;

>. Direct discharge of untreated edging wastewater does not meet national standards.

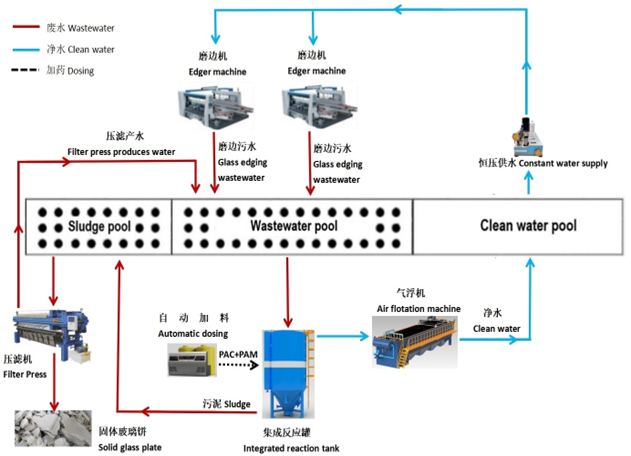

2. Treatment solution for glass grinding water

The high-efficiency all-in-one grinding wastewater treatment machine is a specialized equipment specifically designed for the traits of glass sewage. It primarily hinges on air flotation technology (involving micro-nano bubble generation, subsurface capture, bubble layer interception, etc.) and concurrent sedimentation principles.

The micro-nano bubble generation apparatus utilizes clean water or partially treated return water to inhale and blend air through the micro-nano bubble generator, thereby forming dissolved air water. This is released under reduced pressure within the equipment pool to generate bubbles with a diameter ranging from 0.1 to 20 μm.

The air dissolved in the water precipitates in the form of micro-nano bubbles, which possess a high surface area and adsorption capacity. It can effectively eliminate suspended solids in wastewater of various concentrations. After treatment, a portion of the clarified water (with a reflux ratio of 30%) passes through the circulating working pump, is pressurized into the air-dissolving equipment for air mixing, and the air dissolves into the water.

At this juncture, the air-dissolving efficiency exceeds 95%. The air dissolved in the water is liberated from the water to form a microbubble layer with micro and nanometer-sized particles. This microbubble layer "intercepts" and "filters" the suspended matter in the sewage, significantly augmenting the hydraulic load of the equipment.

The "intercepted" suspended solids ascend to the water surface and form a considerable amount of scum, which is subsequently removed by a chain-type slag discharger installed on the equipment pool to achieve the treatment outcome. The concurrent sedimentation technology is mainly employed to remove particulate matter of large specific gravity in the wastewater.

The wastewater, after mixing and contacting with micro-bubbles, flows downward in an approximately laminar flow state within the separation zone of the device. At this moment, the particulate matter of large specific gravity is regulated by both gravity and water flow. Under the dual action, it rapidly sinks to the bottom of the pool, and a sludge bucket is installed at the bottom of the separation area to fulfill the functions of sludge collection and sludge discharge. A backflush device is incorporated into the sludge discharge pipeline. When the sludge hopper encounters difficulties in sludge discharge, the backflush device is activated, and the sludge at the bottom reverts to a smooth sludge discharge state.

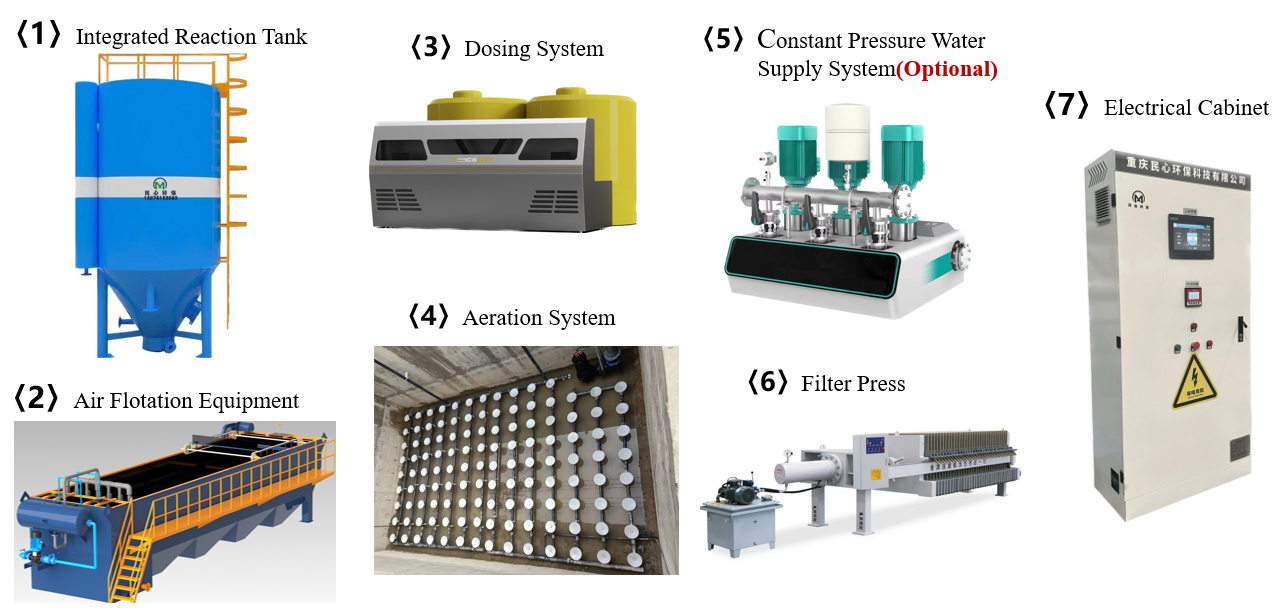

3. Treatment equipment for glass grinding water configuration

4.Treatment water quality effect

| No | Item | Water inlet quality | Purified water quality |

| 1 | PH | Edging wastewater | 6~9 |

| 2 | SS(mg/L) | Edging wastewater | <30 |

| 3 | COD(mg/L) | Edging wastewater | <60 |

| 4 | Color | Edging wastewater | <30 |

| 5 | AMMONIA(mg/L) | Edging wastewater | <25 |

wastewater

clean water

solid glass cake

5. More than 600 installation cases in total